8 Things Your Competitors Could Teach You About Site and Forklift Safety

As at 8 November, 148 Australian workers have been killed at work in 2016. A very sobering thought and a reminder of the dangers at work.

Complacency is often the tipping point where changes around the site only tend to happen once something goes wrong. A quick look around other sites can highlight a few things that you can do to keep your employees safe.

Lets look at 8 Things Your Competitors Can Teach You About Site and Forklift Safety in your facility.

1. Speed Limits:

It sounds logical but you would be surprised to to know that some sites do not display a forklift speed limit within their site and although you may

reiterate to staff about dangerous speeds and what is acceptable - a reminder in the form of signage can only help to point out that a speed limit exists and is enforced by management, in much the same way that a road speed limit is enforced (without the flashing blue lights behind you but in the form of a 'eyebrow-raised' boss). Speed limits for different areas of your plant is critical for forklift safety. It also allows logistic costs to be estimated and calculated more effectively; ensuring better understanding of traffic movement.

Image Source: AisleAlert Forklift Safety Warning Systems

2. Visibility:

A common factor which comes hand-in-hand with warehouses and industrial areas is...noise (sorry what did you say?). Noise from machinery, welding, vehicles, tools and more. Above all the regular day to day noise, factory workers may also wear headsets or earphones/ear muffs to protect their ears from the noise of heavy machinery or simply to listen to the radio while they work. The operating noise from a forklift may seem enough to warn others that it is oncoming, but in reality, forklift noise can easily be drowned out from all the other day to day activity. Do not rely on noise to warn staff / employees / pedestrians of forklift traffic. There should be significant thought into visibility of potentially-dangerous machinery.

Consider the very clever LED Integrated Traffic Lights offered on some High Speed Rapid Roller Doors such as the Remax Movidor High Speed Rapid Roller Door, to warn oncoming traffic/pedestrians that the door is in use. Coloured LED lights will warn forklift users that they cannot enter/to hold back or that the coast is clear and they can continue.

It is vital to improve visibility throughout the workplace in order to reduce risks and improve workplace safety.

3. Maintenance and Upkeep:

Keep, and stick to, a maintenance plan and prioritise upkeep of machinery wherever possible. This applies to not only machinery but also software and products - as with each and every new upgrade or edition; products and software are often improved and have the opportunity to resolve prior safety issues and concerns. It is not often possible to have the best version of everything on site, but the safety features and investment of newer products and machinery will often far out-value the financial and emotional cost of an accident at work.

Maintenance solutions for items such as High Speed Rapid Doors and forklifts can help reduce equipment damage & wear from operator errors. This in turn will reduce maintenance and damage repair costs; such as tyre & tyne wear; overall body damage; hydraulic damage and other basic equipment damage.

4. Traffic Management Plan

It is never too late to check and / or change your Traffic Management Plan. Companies grow/expand/change/decrease (whatever the case may be) and develop as the years go by and it can be easy to let site issues and inefficiencies go untouched from day to day, no matter how annoying the problem is - or how easily it can be changed.

We all do this at home too - how often have you put up with something which really irritates you - maybe it is a dripping tap / a torn or broken floorboard or carpet / a squeaky door or handle and when you eventually get around to fixing it, you wonder why it took you so long?

When an issue becomes the 'norm', they can simply get forgotten. A good look at your traffic management plan and considering any small change could exponentially improve efficiency and have a lot less headaches.

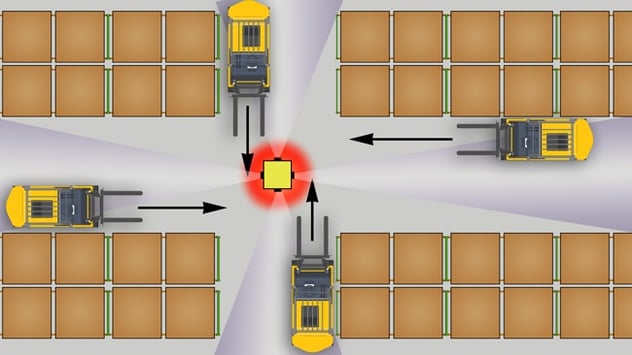

WorkSafe’s general manager of health and safety, Lisa Sturzenegger, said forklifts were a major contributor to deaths and serious injuries in Victorian workplaces.

“Forklifts and people working close by simply don’t mix. A traffic management plan incorporating physical separation of forklifts and people is essential.” she said.

More information on forklift safety can be found at worksafe.vic.gov.au

5. Complacency:

We recently came across a classic example of this where a common manual was recently updated and on the very last draft of the manual, after many weeks of amends/changes and a day before it was approved for printing, a electrician mentioned that a wiring diagram was not right - it always had been wrong in all previous editions and the team onsite all knew about it and worked around it but it was never mentioned to management to get it changed.

Never assume that because everyone else does the wrong thing, that it is the right thing to do.

6. Written Records

We cannot stress the importance of written proof / paperwork / paper trail when it comes to enforcing safety systems at work. Word of mouth is simply not enough. In a 2012 tragedy where a worker was involved in a forklift accident - a freight company was convicted and fined $375,000 over the death of a worker who was crushed by a 635kg computer server that fell off a forklift at its Laverton North depot.

The court was told that the company had failed to enforce an exclusion zone as oversized freight was being unloaded from a truck. While it had a safety policy that required all staff to be at least two metres from working forklifts, the company had no written record that the man had been told of the requirement.

Always be on the safe side and issue safety notices to each member of staff - ask them to read it and sign it and keep this on your records

7. No-Go Areas

In a way - this goes hand in hand with your traffic management plan. It can be fairly inexpensive to install guard railing, bollards and barriers around certain no-go areas of your site, and until something happens, we don't tend to think about it very much. Especially if your staff have been with you for many years - it can be easy to assume that everyone knows the danger zones. Keep this in mind - it could be cheaper for you to protect rather than repair! A small accident can have huge repair costs.

8. Signage

Clear and appropriate signage onsite to guide and assist clients / staff / visitors. Put yourself in the shoes of a visitor coming to site for the first time. Will they know where to go to find the finance department / management / first aid box / toilets?

Site safety can sometimes be improved by simply increasing the speed at which information and assistance can be found.